You make excellent points Jim and I very much agree with them. I just know when I gave up on insisting that hammers in the low tenor and bass sections of the pianos should always be vertical to the strings, life became a little more comfortable. :-) And I'm a big believer in getting the treble hammers vertical as you suggest.

My video on key making is quite out of date now with the new CNC machines, but I'm glad you found it helpful.

Original Message:

Sent: 03-19-2018 21:22

From: Jim Ialeggio

Subject: Squaring fully tapered hammers

Rick,

Thanks for your reply…nice post. I see your point.

I guess one thing we should always be aware of in posting like this is that we each need to be very clear about our assumptions, or about what problem we are trying to address. Its hard to do this, always, with complete clarity. Your post clarified where your point of view was coming from, and from that point of view completely agree…especially dealing with the endemic factory inaccuracies that plague so much of our work.

To clarify what problem I am trying to prioritize in refining my shop process:

1-the procedure is shop related. This level of precision, on-site, has previously been a non-starter for me. This is simply too much to do in too little time to create the conditions I'm creating in the shop. Although this tool is so quick, it is something I've wanted on site for a while. So it may end up with a site life too.

2-The precision I'm referring to, is primarily about notes 45-ish-88. Strings are either approaching 90 deg or at 90 deg to the action stack (ie parallel to the shank travel, or approaching parallel). In top level work, the tonal result is the priority, so simplifying impact has a direct positive tonal consequence. This is one of my big-bangs-for-the-buck processes #45-ish and up. It's a high priority for me, even in one day way-not-enough-time band-aid regulations.

3-In the mid to low tenor agraffes I haven't noticed any problem that squaring can solve, so its not a priority in terms of the precision of squaring. As well, since the squaring from #45-ish to #1, does not seem to have the same tonal consequence as higher in the compass, since strings are at a more acute angle relative to the stack, magnifying potential hammer alignment inaccuracies, and since bores are angled more aggressively, I don't fuss this area the way I do further up. It just doesn't pay the same dividends down there. Not only that, with the soft light hammers I use, I find mating is not that picky either. So, making the compromises required by the as-built inaccuracies makes most sense to me here.

However, in my own shop work, even though verticality is not of great tonal consequence down there, I still vastly prefer to maintain proper alignment without tilting hammers at all, even though tilting is customary in the low tenor/high base. This because, its much easier to come back to the action for follow-up regulations and go through the vertical processes if one knows that verticality is the starting point. I know that on my work, verticality is the starting point, so followups are greatly simplified, and I can really move efficiently and precisely through this part of the regulation. When things are out of vertical, as the vast majority of pianos are #45-1, for my brain, the follow-up becomes more ambiguous, requires more strategizing, and in the crush of time, skipped over or performed only cursorily.

I should say, that I mostly service my own instruments, so setting them up for my own future sanity is another important priority for me.

4- Lets face it…even fine pianos, once on-site, will not get regulation really attended to often or thoroughly. So I want it to leave my shop as clean as I can get it, otherwise it may never be set up anywhere near to its potential.

On a totally different topic, Rick, I managed to get hold of a video you presented at a convention a while ago regarding making keyboards. I've been itching to do this, and the video answered a couple of questions I had be scratching my head about…thanks

------------------------------

Jim Ialeggio

grandpianosolutions.com

Shirley, MA

978 425-9026

Original Message:

Sent: 03-19-2018 07:04

From: Rick Butler

Subject: Squaring fully tapered hammers

Hey Jim, I think to travel first and cast second as you have described is a great procedure to follow; hands down. Your jigs are most impressive. I don't do much if any shop work these days. My son John runs our shop. But when mounting new parts, he travels first and cast's second, just as I taught him.

On occasion, I'm sure we all have observed actions in the field with alignment issues; from the capstans on up. Particularly is this true when it comes to clearance between adjacent hammers. Obviously these instruments have not had the attention given to them as you have given to your actions.

It is mostly from this perspective that I have made my comments. Learning to 'see' the difference between the need to cast and the need to travel as one raises a single hammer toward the string is rather handy. Although separate steps, they are as mentioned, functionally inter-related.

One consideration is how to handle perfectly 'squared' hammers on perfectly 'traveled' hammershanks that will not 'perfectly' align to the strings. When working with angled hammers in the agraffe sections of the piano this can be a particular problem. What are the options? There are basically two; make the hammershank off-center from the wippen, or travel the hammer to the string. Often, the answer is a compromise between the two.

Therefore, learning to 'see' if a hammer is traveling in the same arc as the hammershank, no matter what direction the hammershank happens to be traveling, is a real advantage. Additionally, as Fred mentioned, " an argument can be made for angling the angle bored hammers to account for the mass imbalance". Angled hammers, if perpendicular to the string in the strike position, will have a cant in the rest position. A fact of life.

Given the complexity of what might be involved, I find that I will often cast first and travel second; then re-assess. (but not on new work!)

------------------------------

Rick Butler

Bowie MD

240 396 7480

RickRickRickRickRick

Original Message:

Sent: 03-18-2018 23:12

From: Jim Ialeggio

Subject: Squaring fully tapered hammers

Nope...not this one. Excellent trebles come from obsessing over the precision of the impact, and obsessing over the precision of the terminations. The trick in developing excellent piano tone is to obsess on the things that actually produce results, and don't waste time on stuff that doesn't offer tangible results.

------------------------------

Jim Ialeggio

grandpianosolutions.com

Shirley, MA

978 425-9026

Original Message:

Sent: 03-18-2018 22:56

From: Peter Grey

Subject: Squaring fully tapered hammers

Jim,

Are you sure you're not obsessing about this too much?

😊

Pwg

------------------------------

Peter Grey

Stratham NH

603-686-2395

pianodoctor57@gmail.com

Original Message:

Sent: 03-18-2018 17:27

From: Jim Ialeggio

Subject: Squaring fully tapered hammers

oops forgot the attachment

------------------------------

Jim Ialeggio

grandpianosolutions.com

Shirley, MA

978 425-9026

Original Message:

Sent: 03-18-2018 17:25

From: Jim Ialeggio

Subject: Squaring fully tapered hammers

Just upgraded this idea for WNG shanks. The original works nicely for new shanks before the excess shank is cut off. Because WNG's CF shank is a tube, a #34 drill bit shank fits snugly inside the tube(grind off some of the twist drill part). CA glue the drill shank into a cutoff of a WNG shank, and you have a shank centering tool for the jig.

Just used this setup for 3 iterations of travel, square and align. The 3 iterations are from #45-88, where the precision of the strike really pays off. This is the nicest, cleanest, most precise regulation of this aspect I have done...way easier, faster and proven true than anything I've done previously. Glad I stuck with the concept through the inevitable "rat's that didn't work" steps.

Rick, I have thought about your comment regarding a possible advantage to casting first before traveling. I can't for the life of me figure why this would be so. The travel-sqaure-align (cast I assume) is such a linear progression I can't see what value doing it in another order buys one. Unless, is an on-site, resolve-an-issue-quick kind of thing...in which case I understand it...but not on the bench.

------------------------------

Jim Ialeggio

grandpianosolutions.com

Shirley, MA

978 425-9026

Original Message:

Sent: 03-17-2018 11:53

From: Rick Butler

Subject: Squaring fully tapered hammers

I absolutely agree with Jim that "there is an advantage to breaking the squaring and traveling into two distinct and independent measurements'. And as Fred said, "Travel and square are inter-related functionally. If you travel a shank (shim one side of the flange), that tilts the hammer. So there is no real point to getting some kind of perfect square of the hammer separately of travel." I totallly agree.

One can learn to observe the travel of a single hammer from rest position to strike position (using the adjacent hammers in the rest position as references) and perceive whether or not the hammer is properly cast; as Fred aptly said, it follows "the arc of the shank". Determining the need to cast a hammer, can be separate and independent from the need to travel the shank. Because it is often a separate and independent step, why would it be necessary to perform casting before traveling the shank? Certainly, when mounting new shanks and flanges, there is benefit to carefully traveling the shanks to make them travel as desired. And, when mounting new hammers, one could certainly use some kind of jig if they wish to check the 'squaring' of the hammers on these newly traveled shanks and flanges.

However, in the field, it is my experience that it is very useful to learn to determine the need of 'casting' separate of any traveling issues. In fact, in my opinion, there is an advantage to casting first and traveling second, at least under certain circumstances.

Rick

------------------------------

Rick Butler

Bowie MD

240 396 7480

RickRickRickRickRick

Original Message:

Sent: 03-15-2018 17:01

From: Jim Ialeggio

Subject: Squaring fully tapered hammers

This is in new work...you travel the shank before hanging, before squaring. This initial traveling is accomplished quite efficiently and precisely, without secondary ambiguous effects, with a square, when there are no hammers in the way. Later, after aligning the traveled, squared hammer to its respective string, re-check both travel and square...its iterative. On a bench setup where the alignment of the center string has been recorded and indexed, the alignment, and subsequent iterative backtracking goes pretty quickly and rationally, without ambiguity, on the bench.

To be clear...the techniques used in new work or new hammer shank replacements, are not necessarily the same as as-built actions.

------------------------------

Jim Ialeggio

grandpianosolutions.com

Shirley, MA

978 425-9026

Original Message:

Sent: 03-15-2018 15:27

From: Fred Sturm

Subject: Squaring fully tapered hammers

Travel and square are inter-related functionally. If you travel a shank (shim one side of the flange), that tilts the hammer. So there is no real point to getting some kind of perfect square of the hammer separately of travel. How would you do that? Make it perpendicular to what, the top of the flange? The action rail? (before or after doing travel?)

The only logical alignment of the hammer is along the arc of the shank (though an argument can be made for angling the angle bored hammers to account for the mass imbalance, which will tend to twist the shank on hard blows). And the arc of the shanks is created by travel.

------------------------------

Fred Sturm

University of New Mexico

fssturm@unm.edu

http://fredsturm.net

http://www.artoftuning.com

"We either make ourselves happy or miserable. The amount of work is the same." - Carlos Casteneda

Original Message:

Sent: 03-15-2018 14:49

From: Jim Ialeggio

Subject: Squaring fully tapered hammers

Different approaches...

One point to consider, when thinking about this, is that there is an advantage to breaking the squaring and traveling into two distinct and independent measurements. When a proof is a secondary proof, ie when one proof depends on the precision of another proof, what is actually know becomes squishy, and more time consuming to diagnostically separate. Also, coming back at a later time, it is easier to return the system to a known starting point, if there is a non-ambiguous reading of either square or perpendicular...no guessing.

Also, when aligning a hammer to one side or another of centered on the flange hole in the rail, the hammer, correctly traveled and square will still be striking at 90 deg to the string plane, or as close to 90 deg as its possible to know given micro differences in note to note string plane. Unless of course its a Steinway with cross papered alignment...which can change the square and travel of the hammer...so further iterations, which often never happen, are required.

------------------------------

Jim Ialeggio

grandpianosolutions.com

Shirley, MA

978 425-9026

Original Message:

Sent: 03-15-2018 08:56

From: Rick Butler

Subject: Squaring fully tapered hammers

Squaring Hammers:

I too am a low tech guy when it comes to this issue. What are my objectives? Ideally, I absolutely would prefer the hammer to be perpendicular to the string upon contact. However, it is not alway practical or even possible fo achieve that objective in every instance. Therefore, I think about it this way:

First, the objective of 'burning' or 'casting' is to rotate the hammer on the shank so that it follows the same path as the hammershank. That can be determined by simply observing the hammer as it moves from the rest position to the strike position. Cast the hammer appropriately. It really doesn't matter what direction the shank is traveling. Rotate or cast the hammer so as to make it follow the path of the hammershank.

Second, traveling. Ideally, the hammer will be perpendicular to the string by having the hammershank travel perfectly straight up and down. But that is not always possible. The hammer is ultimately directed to the string by the hammershank. I am assuming the hammershank is centered over the wippen. Of course even here, there is room to move the shank right or left and still have the shank considered to be centered over the wippen. And then, I'm assuming the wippens have been properly spaced. But in the end, traveling gets the hammer to the string.

I feel it is rather important to have everything aligned the best is can be from the capstan up to the hammershank, or to the strings. I also feel it is rather important to have good spacing between adjacent hammers as the hammer travels to the string. And, correct spacing of the hammers to the strings is of utmost significance as is the fitting of the hammers to the strings.

I guess I feel that having the hammer perpendicular to the string upon contact, while ideal, is not necessarily the ultimate objective.

This is not the only way, but at the moment, it is my way.

------------------------------

Rick Butler

Bowie MD

240 396 7480

RickRickRickRickRick

Original Message:

Sent: 03-14-2018 22:02

From: Fred Sturm

Subject: Squaring fully tapered hammers

With hammers already hung, the squaring can be done by using the neighboring hammers as reference points. Precise traveling is a prerequisite. Raise every other hammer, place the key up stop rail below them (or some other spacer), lower the hammers. Center each of the 'up" hammers between its neighbors, sighting precisely at the shank: spaces on each side of the shank should be equal. Remove the rail. Burn the shanks so that the crowns are spaced evenly (even spaces on each side).

Then repeat with the other half of the hammers (odds first, evens second).

While this does not use any sexy tools, it gets the job done quite well. One trick is to use one eye and sight directly in line with the hammer (especially important for angled hammers), so that you can see a wee bit of each side of the hammer. Then look for even spaces precisely at the shank.

The principle is that the shank rises perpendicularly (you created that by doing precise travel). Now you want the center of the hammer crown to be directly above (perpendicular) the middle of the shank.

------------------------------

Fred Sturm

University of New Mexico

fssturm@unm.edu

http://fredsturm.net

http://www.artoftuning.com

"We either make ourselves happy or miserable. The amount of work is the same." - Carlos Casteneda

Original Message:

Sent: 03-14-2018 21:51

From: Fred Sturm

Subject: Squaring fully tapered hammers

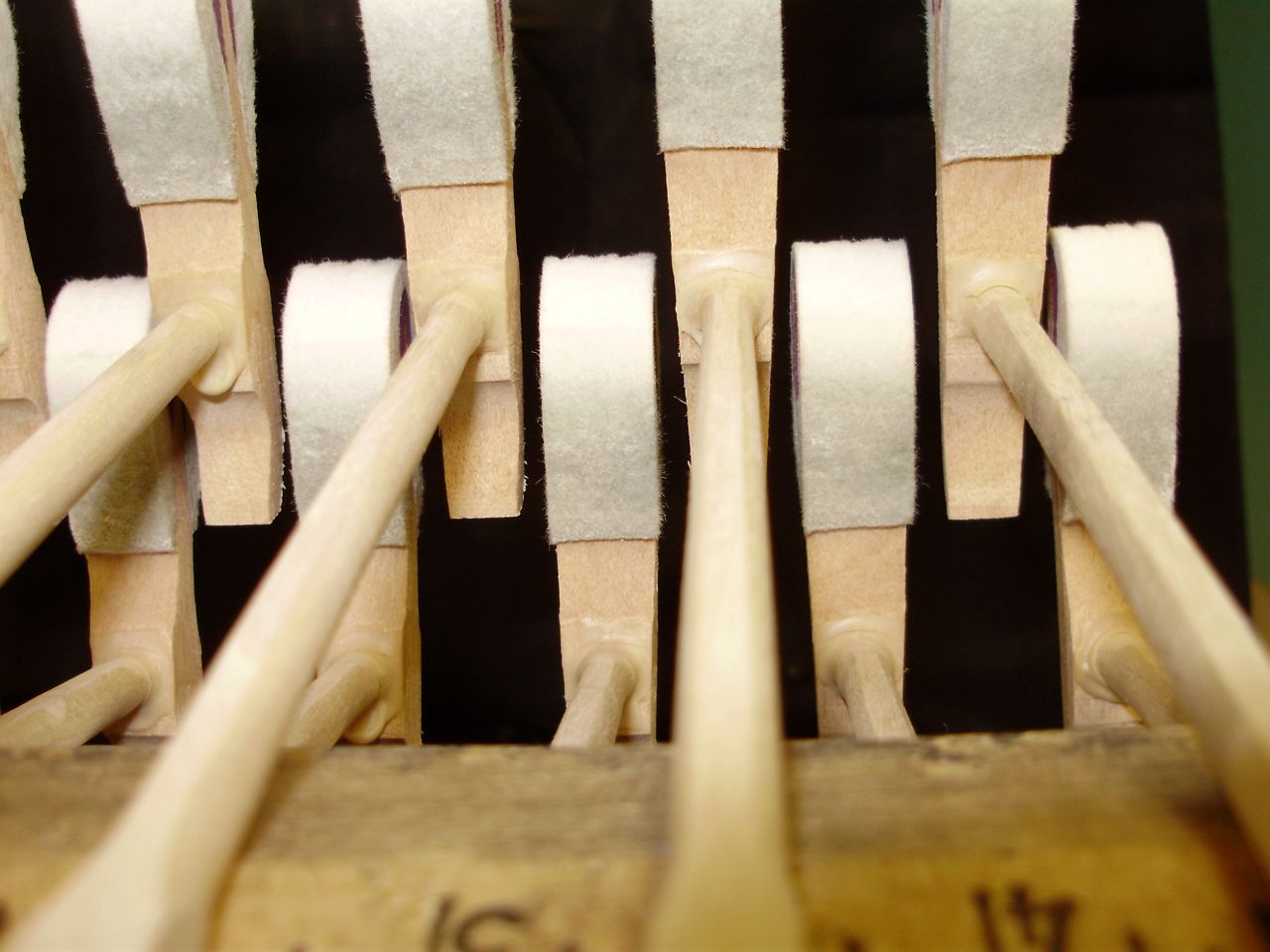

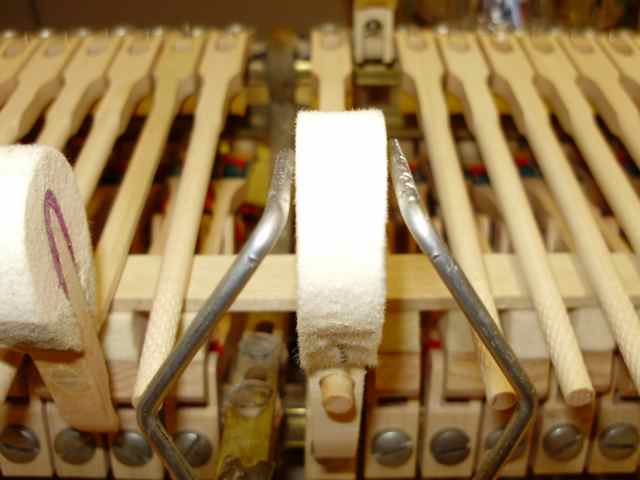

I am a low tech kind of guy. Here is what I use for hanging hammers square (I check every one). It does require that the shanks be pre-traveled, which I do by an upside down method: shanks down on the bench, wippens above them, rock the action up and down, range of motion determined by when the jack tail contacts the let off button.

------------------------------

Fred Sturm

University of New Mexico

fssturm@unm.edu

http://fredsturm.net

http://www.artoftuning.com

"We either make ourselves happy or miserable. The amount of work is the same." - Carlos Casteneda

Original Message:

Sent: 03-13-2018 14:00

From: Peter Grey

Subject: Squaring fully tapered hammers

Glen

Very impressive! Thanks for sharing. Feel free to share more angles. Would love to see more of it.

Pwg

------------------------------

Peter Grey

Stratham NH

603-686-2395

pianodoctor57@gmail.com

Original Message:

Sent: 03-13-2018 03:50

From: Glen Hart

Subject: Squaring fully tapered hammers

The photos uploaded in random order. They are best understood in the following order: 5,1,3,2. The other photos would probably be better on the sanding tapers thread.

------------------------------

Glen Hart

Grand Junction CO

970-434-5558

Original Message:

Sent: 03-13-2018 02:33

From: Glen Hart

Subject: Squaring fully tapered hammers

Hello All, With the belief that a picture is worth a thousand words, here are a few pictures that might be of interest. I've used this system for over thirty years and found it very efficient. -little or no hammer burning afterwards- This is my first attempt to send photos. They appeared to be in reverse order. Maybe not

------------------------------

Glen Hart

Grand Junction CO

970-434-5558

Original Message:

Sent: 03-12-2018 18:12

From: Jim Ialeggio

Subject: Squaring fully tapered hammers

Right, this jig is for a secondary process...ie, squaring after the hammers have been glued to the shanks. Its not used in the gluing process, except to get some sample hammers reasonably close. Using those sample hammers reasonably square, I eyeball the rest. I go back the next day, after gluing the hammers, and then perform the squaring procedure with this jig. The WNG shanks "burn" very easily after the fact, so eyeballing the initial hammer gluing is mostly not an issue. An occasional hammer needs to be popped off and re-glued, but only one or two usually.

------------------------------

Jim Ialeggio

grandpianosolutions.com

Shirley, MA

978 425-9026

Original Message:

Sent: 03-12-2018 16:39

From: Floyd Gadd

Subject: Squaring fully tapered hammers

I like your method, especially for the installation process.

I've been using the Surface Height Gauge from Pianotek to provide a mid-air point of reference. I find this useful when "burning" shanks.

------------------------------

Floyd Gadd

Regina SK

306-502-9103

Original Message:

Sent: 03-12-2018 16:15

From: Cecil Snyder

Subject: Squaring fully tapered hammers

No question your method is waay more accurate. I usually figure I'm going to have to go over things with the heat gun anyway after the glue sets and I'm lining up hammers to strings. Like so many things we do, once through never seems to suffice. I betting a certain amount of that slop is due not only to the limitations inherent in my "base line," but also to movement in the shank itself as it reacts to the moisture in the glue.

------------------------------

Cecil Snyder

Torrance CA

310-542-7108

Original Message:

Sent: 03-11-2018 17:37

From: Jim Ialeggio

Subject: Squaring fully tapered hammers

yup...but indexing an angle off of a 3/8" long reference is, in my view somewhat problematic. As in, a .002" error, that is, an error, which in that setup which would be hard to visually detect, would be projected and magnified up at the top of the hammer. .002 at the tail referecne twists the hammer up at the strike point close to a full millimeter to one side or the other. With that kind of potential projected error, that's why I find the usual ways of squaring somewhat frustrating.

------------------------------

Jim Ialeggio

grandpianosolutions.com

Shirley, MA

978 425-9026

Original Message:

Sent: 03-09-2018 20:52

From: Jim Ialeggio

Subject: Squaring fully tapered hammers

I've been messing with this concept for a couple of years. That is...How does one square a hammer that has been fully tapered on both sides. Reading the geometry is tricky, since one has removed all the reference surfaces in cutting the full tapers.

Double full tapers compound potential measuring error by an order of magnitude. Additionally, proving a taper is equal on both sides of a hammer is unbelievably difficult, as all the original reference surfaces have been removed in the taper. We usually assume that both tapers are the same angle. However, that assumption is fraught with uncertainty. I've made this assumption, like everyone else who does full tapers does, but always was frustrated by it, as I knew how unreliable the assumption was.

So I backed up and tried to define what "square" in this instance actually means, given the fact that reliable references have been removed in the full taper.

Here's my definition of "square" as it relates to a fully tapered hammer…Square means: a line drawn perpendicular to the keybed, up through the center of the shank, projecting through the center of the hammer.

Its easy to visualize the center of the shank part of this definition. The center of the hammer not so easy. So to visualize this second point, imagine that the hammer is being suspended like a plumb bob, its plumb line running through the rotational center of the hammer. This line is the ideal force line we would like to be perpendicular to the strings…in my opinion.

The line through drawn the center of the shank, is a reference which is unaffected by taper work done to the hammer...so that's an undisturbed accurate reference. This line bisects the shank's mass. The line then projects further up, to a point at the center of the hammer felt, at the strike point of the hammer. This point represents the midpoint of the mass of the hammer. The line therefore bisects both the mass of the shank and mass of the hammer.

So this definition represents "square", because the force line bisects the mass of the of both the tapered hammer and the shank. A hammer striking in this balanced fashion will have the greatest tendency to strike perpendicular to the strings, with the least lateral deflection at strike.

So…how does one measure to the center of things? Here's what I'm been playing around with for a while.

This example shows the hammer tilted just a hair to the right in the photo. Note the pencil dot on the strike point just to the right of the 85mm center marking on the rule.

The shank (on a newly hung shank) is automatically centered by the jig…no interpretation, or sighting is necessary. So this first parameter proves itself easily. The jig is oriented perpendicular to the shank ( as shown), whether the hammer has an angled bore or 90 deg bore. One doesn't angle the entire jig to match the bore angle of the hammer. This because the next step, reading a center point at the apex of the hammer, is actually taking a reading from the rotational center of the hammer, as if the hammer were suspended like a plumb bob from a plumb line. The hammer's angle doesn't matter, as I am reading a center point. Its a little hard to think about, but I like this better than anything I've used previously.

I have already marked the strike point with a line while prefiling hammers proir to hanging, in a gang prefile clamp. All I do is eyeball a tiny dot at the center of the hammer width at the already marked strike point.

I'm liking it.

------------------------------

Jim Ialeggio

grandpianosolutions.com

Shirley, MA

978 425-9026

------------------------------