You may want to first use a transfer punch to locate the center of the plate hole.

Original Message:

Sent: 03-02-2024 20:25

From: Norman Brickman

Subject: A Broken Agraffe

Maybe one other question. Normal procedure in drilling in brass is to grind/file the leading tip of the drill bit a little (parallel to the axis) so it doesn't grab on the softer metal. I already have a 7/64" pass hole in placer. Grinding the tip of the bit will somewhat decrease the dual use of the drill bit as an EZ-Out, but I think that is better than risking a hard seizure. Agree?

------------------------------

Norman Brickman

Potomac Piano Service

Potomac, Maryland

potomacpiano@verizon.net

https://potomacpiano.com

(301) 983.9321

Original Message:

Sent: 03-02-2024 10:48

From: Norman Brickman

Subject: A Broken Agraffe

All excellent help -- appreciated. I just ordered a 1/4" hex drill chuck – should give me the plate clearance that I need without use of a long bit (one needs to be careful not to get a threaded one that is not meant for counterclockwise use!). I have a 7/32x36 tap on order, and I already have a good set of steel punches that I'll bring with me if needed. It might be a couple weeks before I get status back to you all. Thanks again.

------------------------------

Norman Brickman

Potomac Piano Service

Potomac, Maryland

potomacpiano@verizon.net

https://potomacpiano.com

(301) 983.9321

Original Message:

Sent: 03-02-2024 09:46

From: James Kelly

Subject: A Broken Agraffe

You can try to fit your drill with a 90 degree chuck (AKA right angle) designed to get in tight spaces. I have a Milwaukee M12 that has interchangeable chucks including a right angle chuck. The cordless Dewalt I have has a gyro in it the more you twist your wrist with your finger on the trigger the faster it goes . It gives extremely good control. Both drills have clutches

------------------------------

James Kelly

Owner- Fur Elise Piano Service

Pawleys Island SC

(843) 325-4357

Original Message:

Sent: 03-02-2024 09:31

From: Paul McCloud

Subject: A Broken Agraffe

If you manage to get a drill bit in there, sometimes you'll find yourself drilling farther and farther down, even coming out the other end. Just use the next size up. Often I find that I'm halfway into the stud and it finally bites. Those Steinway agraffes are tight in there, as I have experience. You might also try using a freeze spray or heat it up with a soldering iron or mini torch. I'd try penetrating oil like PB Blaster, but I'm not sure it would help that much. Tight is tight.

I have also seen long shank left handed bits on Amazon and other places. Might be worth a call to a local tool dealer. Good luck!

------------------------------

Paul McCloud, RPT

Accutone Piano Service

www.AccutonePianoService.com

pavadasa@gmail.com

Original Message:

Sent: 03-01-2024 22:02

From: Norman Brickman

Subject: A Broken Agraffe

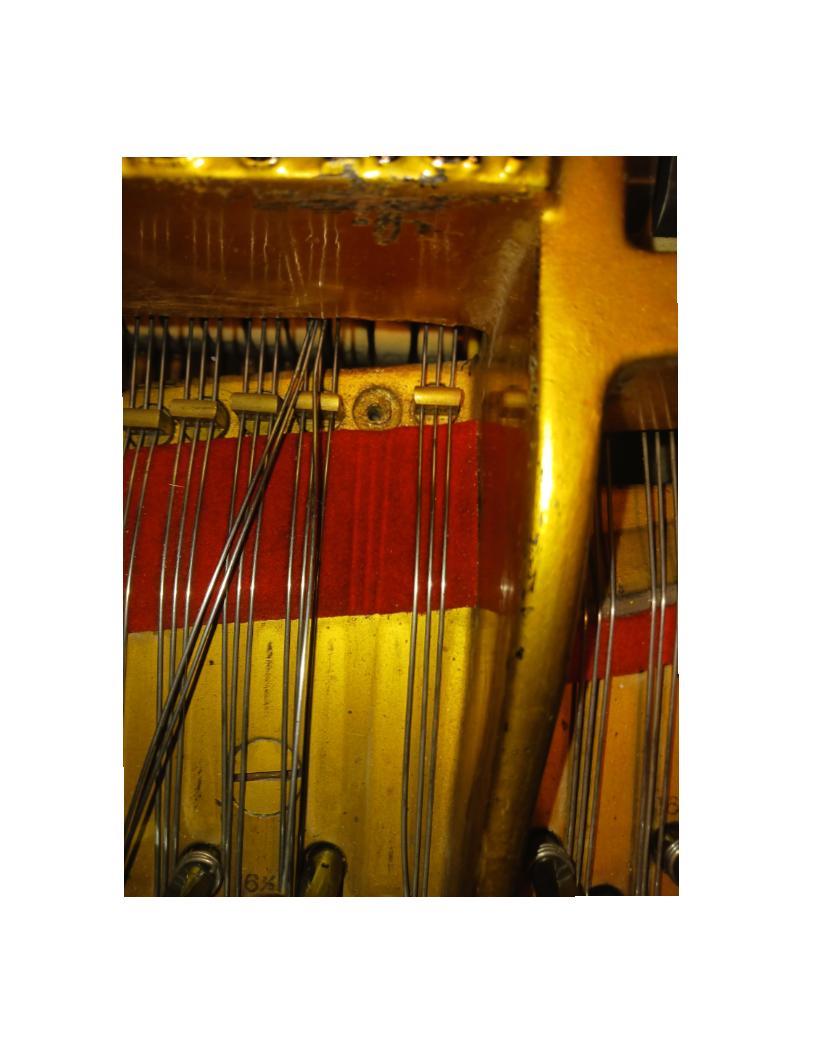

I am working on 1915 Steinway Model O with a broken agraffe at C#5. I was unable to manually turn it out (like I normally do) so I drilled through the remaining core to use a #2 EZ-Out. It won't turn, and I don't want to take a chance on breaking off the EZ-Out with a hard twist. See the picture.

Are the agraffes on this piano 7/32"x36 or 1/4"x36? I lean toward, next, drilling and trying an EZ-Out #3. If that fails, then drilling and tapping for the new agraffe. Any help/suggestions would be appreciated. Regards, Norman.

------------------------------

Norman Brickman

Potomac Piano Service

Potomac, Maryland

potomacpiano@verizon.net

https://potomacpiano.com

(301) 983.9321

------------------------------