While this thread has drifted a bit from the initial scope of the KMD, Jude posted his mini EoB/Stanwood calculator at the request of myself and others. I saw a snippit of it in Reno and he had called me on another subject and I asked him about it so he posted it. And, DL, thank you for your additional input. I'm still in the process of wrapping my mind around what I now call Stanwood/Reveley/Love/Gravagne grand action concepts. Names are in no relevant order. Now I will jump over to the spreadsheet thread. I thank everyone for their input!

Original Message:

Sent: 02-11-2025 14:41

From: David Love

Subject: KMD Renner Key Measuring Device Comparison to tradional method

I don't quite agree with the analogy. I think some of the complaints (customer) I've had with some (not all) Stanwood executions is the choice about level of inertia. There is/was/can be an attitude that if some low level of inertia is desirable then more must be better. Levels which are too low, for high level pianists especially, can be just as troublesome as those which are too high. A lack of feedback plus dip levels which are excessive if the low level was achieved through a low SWR or AR are problematic.

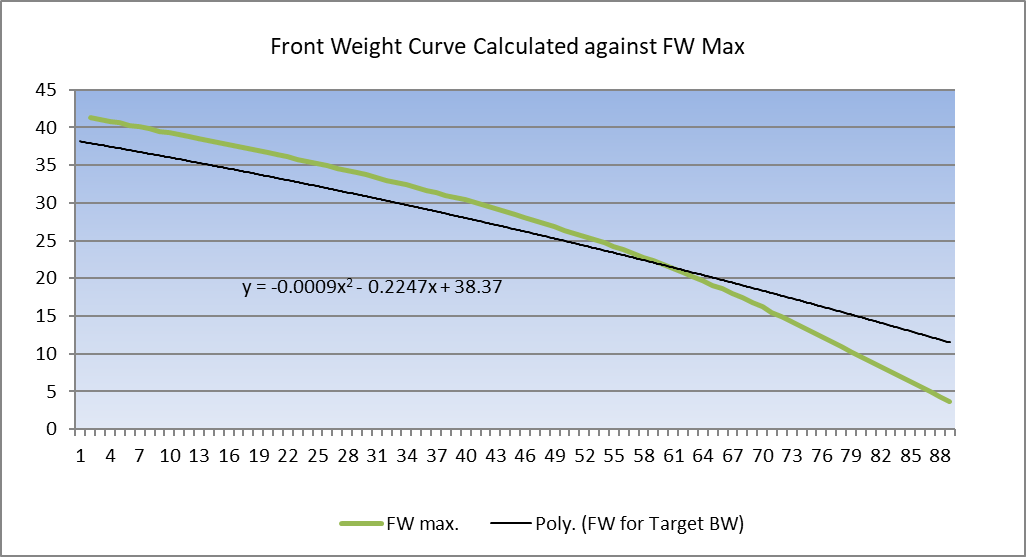

The spreadsheet is nice but all those inputs are really unnecessary. The level of inertia, I believe, falls within a pretty narrow range and is mostly determined by the AR:SW relationship. The contribution of the rest of the action parts (including lead) is pretty minimal. There is some disagreement about what the contribution of that relationship amounts to but for all practical purposes it's what you have to worry about. That sweet spot of inertia is achieved when the FW falls about in the 80-85% of Stanwood FW maximum range if you keep the BW constant and about 36-38 grams (normal range). A lower FW means one of two things; either the AR is lower or the SW is lower. Since that relationship is what determines inertia levels a lowering of either one will lower the inertia. That's all you need to know. So simply preset your FWs to that, let's say 80% maximum FW and sample different SWs until you get the balance weight you want. The KMD makes that check very easy. Do that in several places across the keyboard, 6 is enough, plot it in an excel spreadsheet, calculate a trendline curve as a 2nd degree polynomial (Y = aX^2+bX+C) where X is your note number, and your Y output will be the SW for each note. You can use the same process to calculate a smooth FW curve once you have assembled the action.

If you want shallower dip, use lighter hammers and shorter knuckle hangings but the FW/BW targets will be the same. If you have a high SW, you'll have to use a longer knuckle hanging (or move the capstan appropriately) but the FW/BW target is the same. Those AR differences will manifest in the action regulation so you must keep that in mind.

It's pretty easy and all the systems in which countless measurements are taken (Gravagne, Stanwood, Voit, Fandrich/Rhodes, etc) all come to the same conclusion if you analyze them. The limits of what we can achieve will be determined by the limits of acceptable regulation specs as determined by the AR. There are sometimes choices to be made where you might be driven more by regulation specs than weight specs and if that's the case and you want to hit the sweet spot of inertia then you have limited choices. ARs will be predetermined because of those regulation limitations and that will necessarily put limits on the range of SWs IF you have an inertia target in mind. There is no way around that (assist springs are a separate discussion).

So that gets you there fast, it's easy, no muss no fuss, you just need minimal skills on excel. I was planning to write a journal article on the subject and still might but, honestly, that about covers it except for the step by step (if you need them) details. Anyone can do this themselves. You can modify your own targets to your, or your customer's, personal taste, or be a renegade and operate outside of normal parameters with super low inertia and 12 mm keydip. I've seen things close to that.

------------------------------

David Love RPT

www.davidlovepianos.com

davidlovepianos@comcast.net

415 407 8320

Original Message:

Sent: 02-09-2025 17:14

From: Jude Reveley

Subject: KMD Renner Key Measuring Device Comparison to tradional method

This is the beauty of the Equation of Balance. It can be adapted to your own style of working. I can recall detractors stating that they didn't like the way a particular "Stanwood" action felt. I always felt that was like saying, "I don't like this particlular house because the carpenters used a tape measure."

My own preference is to choose my hammers accordingly, and that is NOT by relying on whether they are made from a 14 or 16 lb sheet of felt. I remove my hammers off the stack after hammer hanging and processing, and then I create a "least work" curve with a third degree polynomial. It is necessary to format the number of the Trendline Label within the equation to around 20 decimal places or you'll off by about a gram by the time you get to not #88.

I am attaching my Equation of Balance Calculator (really Stanwood's Calculator) that many of you have asked about. Have fun!

------------------------------

Jude Reveley, RPT

President

Absolute Piano Restoration, Inc.

Lowell, Massachusetts

978-323-4545

www.absolute-piano.com

Original Message:

Sent: 02-04-2025 12:48

From: David Stanwood

Subject: KMD Renner Key Measuring Device Comparison to tradional method

Thanks all for the feedback. Time will tell as to the similarity of KMD to conventional U/D. I'll report back when I've had a broader feedback. The tool is great and has a lot of potential. Thank you Skyler and Renner!

------------------------------

David Stanwood

stanwoodpiano.com

stanwood@tiac.net

508-693-1583

Original Message:

Sent: 02-04-2025 12:29

From: David Love

Subject: KMD Renner Key Measuring Device Comparison to tradional method

David S.

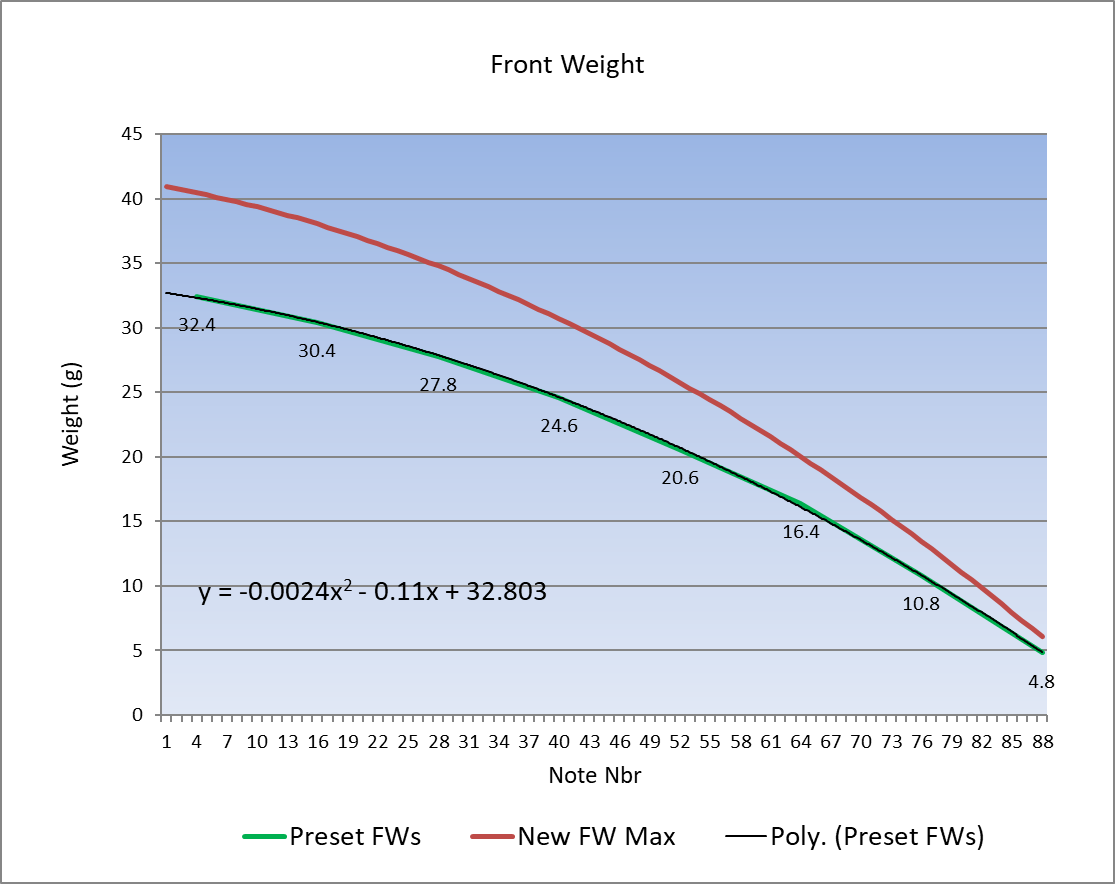

I'm glad to hear you've been teaching it. It doesn't seem to be a procedure largely followed by that many people or that people are even aware of but is clearly the simplest and most direct way to predetermine not only SW targets but inertia levels as well. Modest skill with excel makes the procedure quite easy and excel can then also be used to create a smooth FW curve. It also allows you to shape SW curves to your own taste. The current standard, as given by your charts and others, is a 2nd degree polynomial shaped something like this (this is a FW curve but the same applies to SW curves).

But there's really no reason it can't be straight line, like this black trendline:

In fact, some hammers come out of the box much more like that (Renner BPs, for example with somewhat lower midrange hammer weights). I don't see any compelling reason the SW curves need to follow ta specific shape, and historically they don't.

But I digress.

If the KMD is marginally different than the traditional method, I don't think it's a big deal. 3-4 grams is a lot though, I haven't had the experience of that much discrepancy other than what I mentioned. Ending up needing a heavier hammer than you calculated for is not a big deal, ending up with one that needs to be lighter can be.

However, I use a default action "slider" method anyway to make the action quasi adjustable. Attach mini binder clips to the shanks as high as you can as part of the calculated SW. Balance the action as light as you think the player may want and then, if they decide they want it heavier, just slide the clip down toward the hammer. That will increase the SW and along with it the BW and the inertia. The mini binder clip weighs about .7 grams so it's effect, depending on position, will be .7*AR*position on the shank. So, if positioned all the way toward the hammer, maxing out at about .8 of the shank length, you can add about 3 grams to the balance weight and the proportional amount to the inertia. Saves a trip back to the shop to satisfy a finicky customer.

FWIW, I have found that with a lower FW% at a set BW target (which yields a lower level of inertia), it is often the case that a higher balance weight is more desirable. For example, if, say, 80% of FW max at 37g BW is the sweet spot (my target is generally 80 - 85% at between 36 and 38 BW, depending pm various factors--at least through the lower 2/3 of the action, above that it's less important) and you set up the action with, say 70% of FW max, the action will not only tolerate a higher BW but it might be more desirable for the player. The reasoning; as the inertia gets lower, it may be advantageous to raise the BW (the BW or DW is basically the minimum force required to actuate the key) so that the player has a better sense of where the hammer is in space from the outset. Most higher level players I work with are more bothered by actions which are too light, or where the inertia is too low, than those that are too high (within reason). As techs we kind of get obsessed with the latest thing, in this case low inertia actions. But, often, our obsessions are not connected to reality.

If some is good, more isn't always better--though it is the American way.

------------------------------

David Love RPT

www.davidlovepianos.com

davidlovepianos@comcast.net

415 407 8320

Original Message:

Sent: 02-04-2025 10:02

From: David Stanwood

Subject: KMD Renner Key Measuring Device Comparison to tradional method

David L, What your doing is just like my SNAP method which I've been teaching and distributing for many years now. I'm all for it. Preset a test FW as a design choice on sample notes in the middle of the keyboard. Then determine the SW that yeilds the desired BW and use the results as a guide for designing hammer weight and front weight scales. My issue with the KMD is that if the BWs are truly higher than what we're getting with conventional U/D measuring then a lighter hammer will be indicated to produce a desired BW using the KMD. So it's important to know how the KMD relates to traditional method.

------------------------------

David Stanwood

stanwoodpiano.com

stanwood@tiac.net

508-693-1583

Original Message:

Sent: 02-04-2025 01:39

From: David Love

Subject: KMD Renner Key Measuring Device Comparison to tradional method

Jude

The way I do it now the AR or SWR play no role. The Reno class was the first presentation of that method but it's evolved to be simpler in execution and explanation. Working on a journal article but trying to figure out how in depth to go with spread sheet explanations for creating curves and smooth weighting.

But working that way I don't need but a single reference for weight without concern about distance so I just need consistency.

Happy to talk about it sometime and would love to see the spreadsheet.

------------------------------

David Love RPT

www.davidlovepianos.com

davidlovepianos@comcast.net

415 407 8320

Original Message:

Sent: 02-03-2025 12:55

From: Jude Reveley

Subject: KMD Renner Key Measuring Device Comparison to tradional method

Thanks for your insights as always, DL. BTW I still need to give you a tour of my Touchweight speadsheet...

I do use the Stanwood jig for FW and I place it under the very front edge of the key, not to piss anyone off here, but to be consistent with my own thinking. I also had my son 3D print a new spacer for the KLD that brings me to the front edge of the key. Not sure how to handle the sharps yet. I am one of those that is very intersted in comparing distance and SW ratios, and this change defintely brought some consistency to the process; however, it doesn't always work out and I am trying to understand why. Stanwood blames gravitational vectors. I gues we all have to choose our hill to die on! :)

------------------------------

Jude Reveley, RPT

President

Absolute Piano Restoration, Inc.

Lowell, Massachusetts

978-323-4545

www.absolute-piano.com

Original Message:

Sent: 02-03-2025 12:22

From: David Love

Subject: KMD Renner Key Measuring Device Comparison to tradional method

Jude

Although, the 13 mm roughly corresponds to the place where the front weight is taken if you use the Stanwood jig (more like 11-12mm). BTW if you use a gram weight of diameter 17 mm (which is what the ones I use are) and you put the edge of the weight at the front edge of the key, then the center mass of that gram weight would be 8.5 mm from the front of the key so it's not really measuring from the front edge. So, there seem to be multiple measurement points that will create some inconsistency from method to method and person to person.

I do use the spacer when taking measurements with the device as for my purposes it's just a matter of consistency of placement and that spacer makes it easy to duplicate that each time. Honestly, I don't think it really matters unless you are comparing two different people's findings. However, it does bring in to question methods of trying to accurately determine action weight ratios especially as they correspond to distance ratios. There, points of measurement will make a difference. Since I don't really use or target action ratio numbers in my own method it's not important. But for those who are trying to hit a certain action ratio target it probably is.

I don't know if it's necessary to have it plugged in but in this one instance certainly the batter charge seemed to make a difference. I'll have to try and duplicate those findings to have some greater confidence that that's what it was.

------------------------------

David Love RPT

www.davidlovepianos.com

davidlovepianos@comcast.net

415 407 8320

Original Message:

Sent: 02-02-2025 19:09

From: Jude Reveley

Subject: KMD Renner Key Measuring Device Comparison to tradional method

Very Interesting DL. The instructions do say that when the KMD is calling data into the app through Bluetooth that it is a battery hog. Maybe we should keep it plugged in when measuring. I've been talking to Skylar about summer of the discrepancies I've been finding, but I am optimistic about having a device that will clear up some of the measuring discrepancies we already experience. I propose we standardize measuring to the outside edge of the key for more consistency with the distance ratio. The 13 mm the Dom Galt suggested as where pianists play is obsolete. Robert Springer recently suggested to me that we define the distance from the fulcrum and express a true torque measurement in newtons. I agree with him. I think we'll find different specs for concert grands than small baby grands.

------------------------------

Jude Reveley, RPT

President

Absolute Piano Restoration, Inc.

Lowell, Massachusetts

978-323-4545

www.absolute-piano.com

Original Message:

Sent: 02-02-2025 16:25

From: David Love

Subject: KMD Renner Key Measuring Device Comparison to tradional method

FWIW, after reading your post I went to an action that I just done and the measurements were all over the place and inconsistent from one to the next and under what I thought they had been by anywhere from 3-7 grams. I noticed that the battery was at about 60% so I recharged and remeasured this morning and it measured both consistently and accurately when compared with using gram weights. I don't know if that was a one time anomaly or what but I will allow the battery to run down some and try again. Should probably be looked into though.

------------------------------

David Love RPT

www.davidlovepianos.com

davidlovepianos@comcast.net

415 407 8320

Original Message:

Sent: 02-01-2025 13:28

From: David Stanwood

Subject: KMD Renner Key Measuring Device Comparison to tradional method

I'm starting to take measurements with Renner's new KMD - Key Measuring Device. I'm finding that the results are generally higher by 3 or 4 grams than those taken with the traditional Down Weight by finding the weight that causes the hammer to rise in a controlled motion after a few light raps to get it started and mirroring that motion with Up Weight. I expect the consistency with the KMD will be much less subjective and way more consistent than the traditional method and it's way faster. Any one else have input on this?

------------------------------

David Stanwood

stanwoodpiano.com

stanwood@tiac.net

508-693-1583

------------------------------