I made a mistake,, oops, the cloth from Pianoforte comes in 1/10 millimeter increments. The total shrinkage is still the same so after dividing in half the (mortise-pinsize), you add .25 per side. The amount of water that dries out of the glue is what you are guessing. Cecil's post that says the type of wood makes a difference is very true. Plus, as said, letting the bushings cure another day after removing the cauls is needed. I find where I live the humidity levels are so low the dry time is cut in half.

This method puts you in the ballpark where the easing is not excessive and easing probably helps create a solid platform for the cloth instead of crushing too much wood.

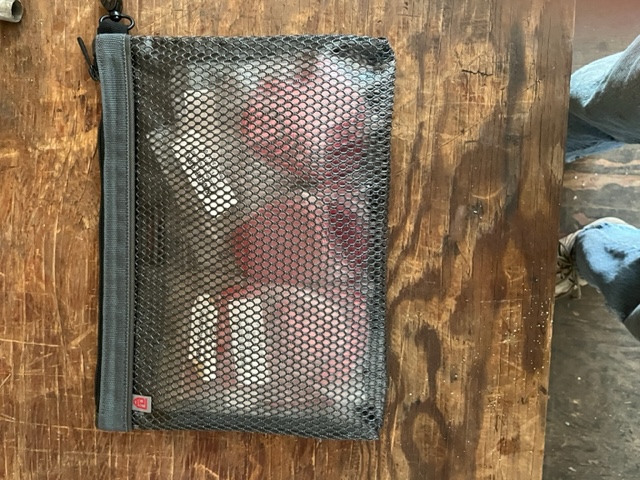

I just got some new storage bags, I have enough of each size cloth to do a full set of keys. I always seem to get the weird ones.

------------------------------

Keith Roberts

owner

Hathaway Pines CA

(209) 770-4312

------------------------------

Original Message:

Sent: 07-17-2023 18:45

From: Ed Sutton

Subject: mix key bushing cloth sizes?

This card is at the top of my bushing cloth bin. It enables me to quickly test and decide on the best thickness for the job. Hopefully I have a lifetime supply of Pianotek cloth, since I am also out of business!

------------------------------

Ed Sutton

ed440@me.com

(980) 254-7413

Original Message:

Sent: 07-17-2023 14:57

From: Cecil Snyder

Subject: mix key bushing cloth sizes?

My experience with measurements in key bushing has led me to not put a lot of faith in them. There are several imponderables that can have a noticeable effect on the end results. The hardness of the wood, both in the key sticks for the front rail and in the key buttons for the balance rail; the kind of glue you use; how well sized the bushing cloth is; what process you used to remove the old bushings. . .all these things can affect the finished result. For that reason I do samples of different size cloth. It's not just more reliable, it's also faster--though not in the sense that you get instant results. You still have to wait for the bushing cauls to come out (24 hours) and then a day for the cloth to settle, but in the meantime you can move on to other stuff. The longer you leave the cauls in the more stable and uniform the result. On the other hand, if I have a set of keys where there is a lot of variation in the mortises due to wear or degraded wood, I'll take the cauls out sooner for a tighter fit and even everything out by easing the keys. Where the mortises exhibit a lot of difference it's usually because the word itself is spongy.

There are other things that are important to achieving a uniform result. When I buy bushing cloth I buy a large quantity of it because even the cloth of the same supplier will vary in thickness over time. ( Keep in mind you'll seldom need the thin and I only use the thick under duress because it's prone to swell under humid conditions.) Likewise I stick to the glue I prefer, because I'm used to working with it and it gives a predictable result.

------------------------------

Cecil Snyder RPT

Torrance CA

(310) 542-7108

Original Message:

Sent: 07-16-2023 18:26

From: Ed Sutton

Subject: mix key bushing cloth sizes?

Bill Spurlock recommended doing this when necessary to get a good fit.

Check his articles and you may find it in print.

------------------------------

Ed Sutton

ed440@me.com

(980) 254-7413

Original Message:

Sent: 07-15-2023 20:47

From: Scott Cole

Subject: mix key bushing cloth sizes?

Has anyone every mixed two different sizes of bushing cloth for key bushings? On my current rebushing job, medium thin is too thin, and medium is too thick.

I suppose I can ease the medium down, but just wondering if there's an issue with mixing sizes. Would it really change the regulation?

------------------------------

Scott Cole, RPT

rvpianotuner.com

Talent, OR

(541-601-9033

------------------------------